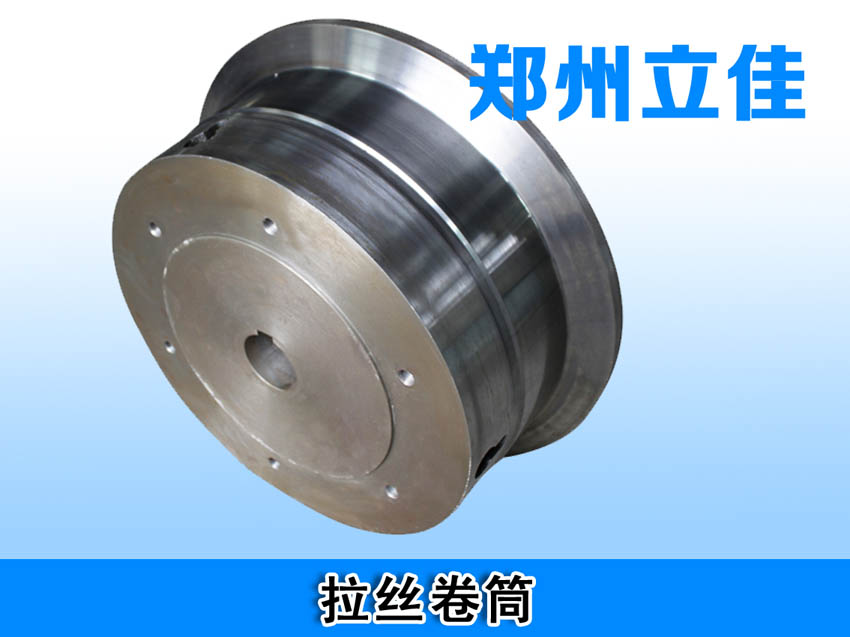

Reel in drawing process improve the drawing force, between the drum and wire transfer is relying on the outside of the drum and the friction between wire, drum under friction wear.Drum surface contact with the steel wire, in water lubrication under dry friction condition on the surface of the steel wire drawing of high pressure, and steel wire drawing heat in great quantities, therefore, drum is a bear high temperature, high wear quick-wear part.

Drum wear directly affect the quality of steel wire surface, rapid wear leads to the increase of production cost and low production efficiency.According to the substrate material, the drum can be divided into cast iron, cast steel, low carbon steel, high carbon forged steel, medium carbon steel, etc.Different substrate material, the use of their own after surface treatment, there will be a different wear patterns.

Drum wear resistance depends on the hardness of surface coating, also depends on the strength and hardness of the substrate.The above 5 types, base shear strength of cast iron drum, anti-wear material wear and adhesive wear ability is poor.Soft substrate material of low carbon steel drum, poor ability to resist plastic deformation.The strength and hardness are higher in high carbon steel drum wear resistance significantly better, especially after surface hardening and surface coating treatment of medium carbon steel drum wear resistance is better, reel in a state of low wear for a long time.

Using supersonic flame spraying technology in drawing drum, wire drawing machine, wire drawing, wire, wire drawing cylinder, wire collecting plate, groove parts such as surface coating carbide coating, can make the surface hardness of HRC75, far more than grinding tool steel or chilled cast iron of high wear resistance;Still can make these parts matrix using ordinary steel or cast iron manufacturing, both to reduce costs, and prolong service life.

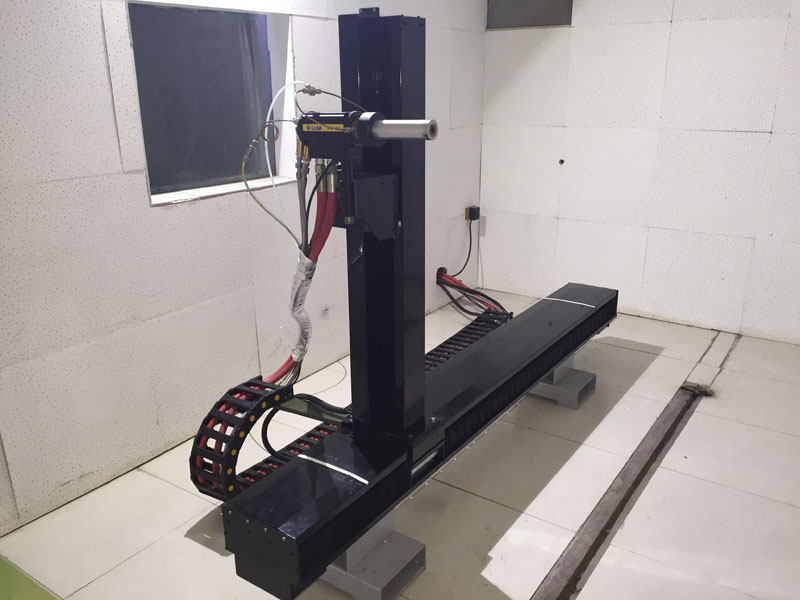

Zhengzhou; thermal spraying machinery co., LTD. As the leading enterprise in henan thermal spraying industry, is a professional engaged in research and development of thermal spraying processing and equipment manufacturing of high and new technology innovation enterprise, the company production of supersonic flame spraying equipment, and undertake all kinds of spray processing and mechanical processing business, the thermal spraying technique power is strong, after the hot spraying coating design and coating processing, supersonic flame spraying equipment has experienced, innovative ideas, to solve some key problems in the field of thermal spraying related applications.The company has more multi-purpose spraying room, equipped with a robotic arm, complete all kinds of tooling, can ensure good coating quality.Company also is equipped with lathes, milling machine, drilling machine, and the universal grinding machine can undertake various mechanical processing business, and coating surface grinding business.

The company's aim is: to create the world first-class technology and equipment, to provide customers with high quality and high quality service, honesty, innovation and progress.Actively accept user valuable advice in equipment use and coating processing.Wholeheartedly for the users from all walks of life both at home and abroad to provide quality service!